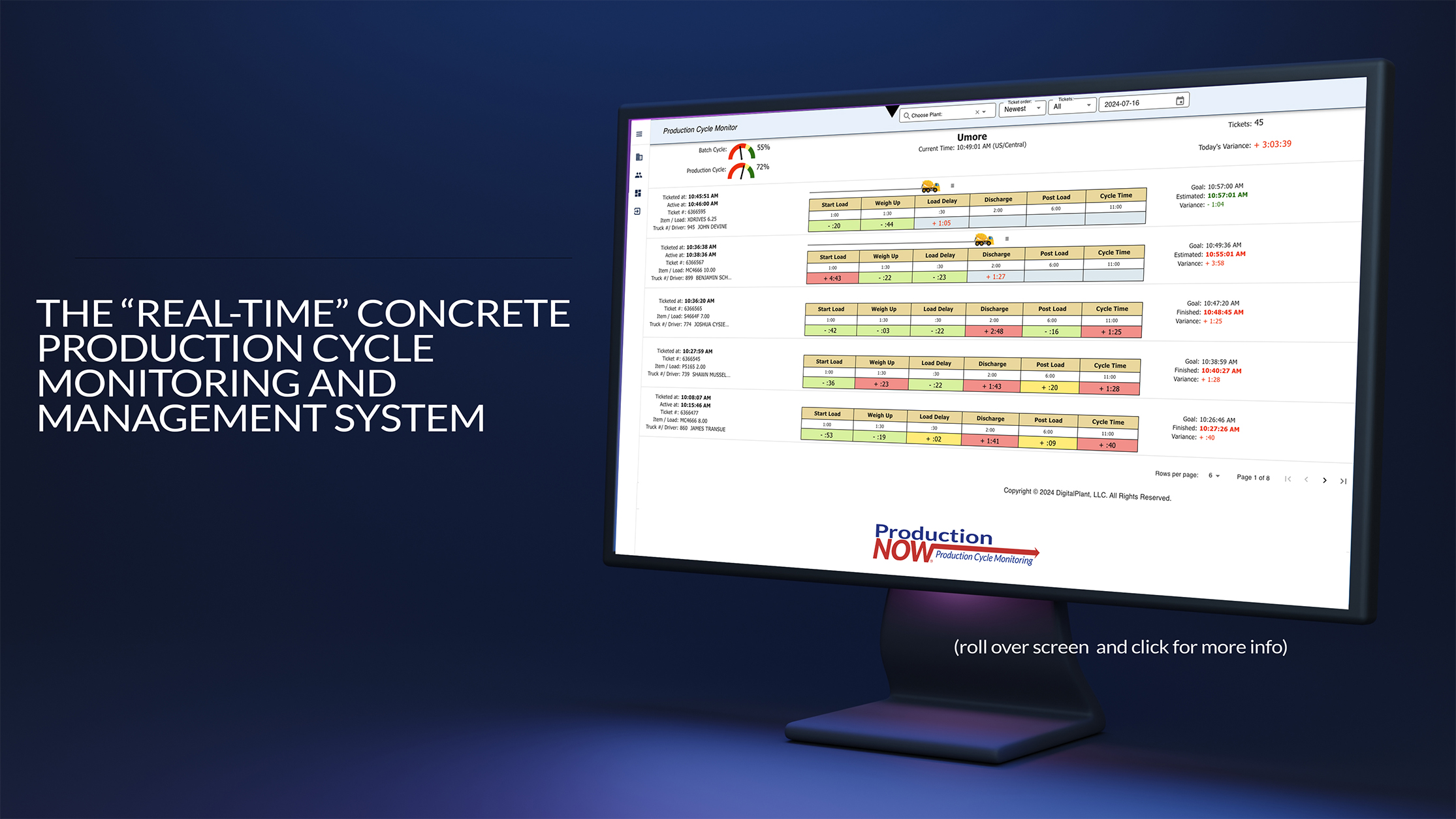

Batch and Production Cycle Meters

The Batch Cycle is from the start of weighup until the end of the material discharge plus the tail water. The batch cycle % is the number loads that completed the batch cycle on time (or early) / the total tickets that completed the batch cycle.

Production Cycle is from the time that the ticket was sent (and the plant is available) until the truck leaves the yard. The Production cycle % is the total number of tickets that are on time (or early) over the total number of tickets that have completed the production cycle.

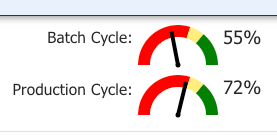

Ticket Information

The ticketed time. Is when the batch control system received the ticket.

Active is when the plant is available (after the ticket was received)

Ticket number is the ticket number that comes from the automated dispatch system.

Item is the Mix Item Code

Load is the loadsize

Truck/Driver is the truck number and the driver of that truck today.

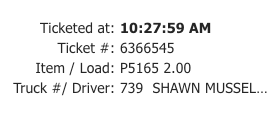

Ticket Progress

Start Load is the amount of time from when the ticket was received (and the plant is available) until the weighup button was pressed by the plant operator. The gray number is the target for Start Load.

Weighup is the amount of time from when the material weighup started until weighup end. Another way to say this is the amount of time from when the plant operator pressed the start weighup button and the plant is available. (I don’t think that you want to use the second explanation because no one will get it)

Load Delay is the amount of time from when all scales are weighed up until the material discharge starts. The load delay would include the headwater if the headwater is not completed before the discharge button was pushed. (not sure if the second statement is necessary)

Discharge is the amount of time from when the material discharge started until the end of the material discharge plus the tail water. Another way to say this is the amount of time after all scales are weighed up and the plant operator has pressed the start discharge button.

Post Load is the amount of time from when the truck was completely loaded until the truck leaves the yard. Another way to say this is the from the time that all of the scales are weighup and the plant operator pressed the discharge button until the tail water is complete.

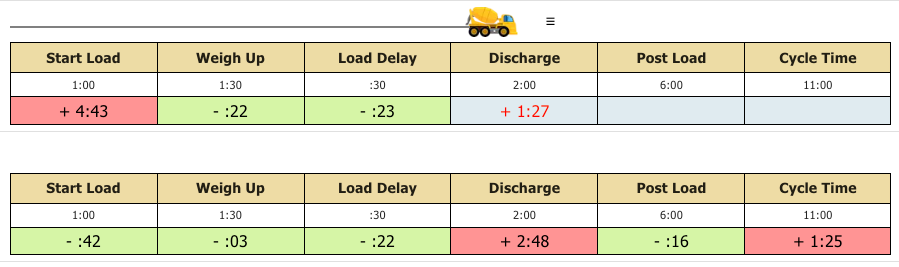

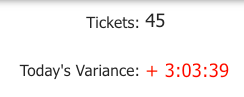

Daily Ticket Totals

This shows the total number of tickets for the day even if the production cycle isn’t complete. The variance is the total variance from the targets (input from management) vs. actual. The variance only gets updated when a load finishes the production cycle.

Ticket Status

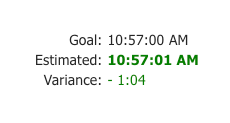

The goal is the total amount of time from when the plant is available (and the ticket was received) until the truck leaves the yard.

The estimated time is the time that the truck should leave the yard. It gets updated every time that a status (or stage is complete.

The variance is the amount of time between the goal and the actual. This field also gets updated after a status is complete.

Don’t let your concrete production cycle be a total mystery. “Where did the time go? Why did we run out of materials? Have you seen the truck and driver?” Let ProductionNOW solve the mystery inside “The Production Zone”.

“You Can’t Manage what You Can’t See”

“Production NOW” uses a simple philosophy of “you can’t manage and improve what you can’t see nor totally understand”. Once detailed production cycling information becomes available, it opens a whole new world of opportunities:

In short, “ProductionNOW” is more than just software to gather data. It is a production performance management tool both from the aspect of the mechanical side and the human side. When both are working hand in hand at their highest operating levels, excellence can be achieved.

Ready to find out what is happening during batch production? Contact us today to learn how our monitoring solutions can transform your operations.